What is Computed Tomopgrahy, commonly known as CT-scan?

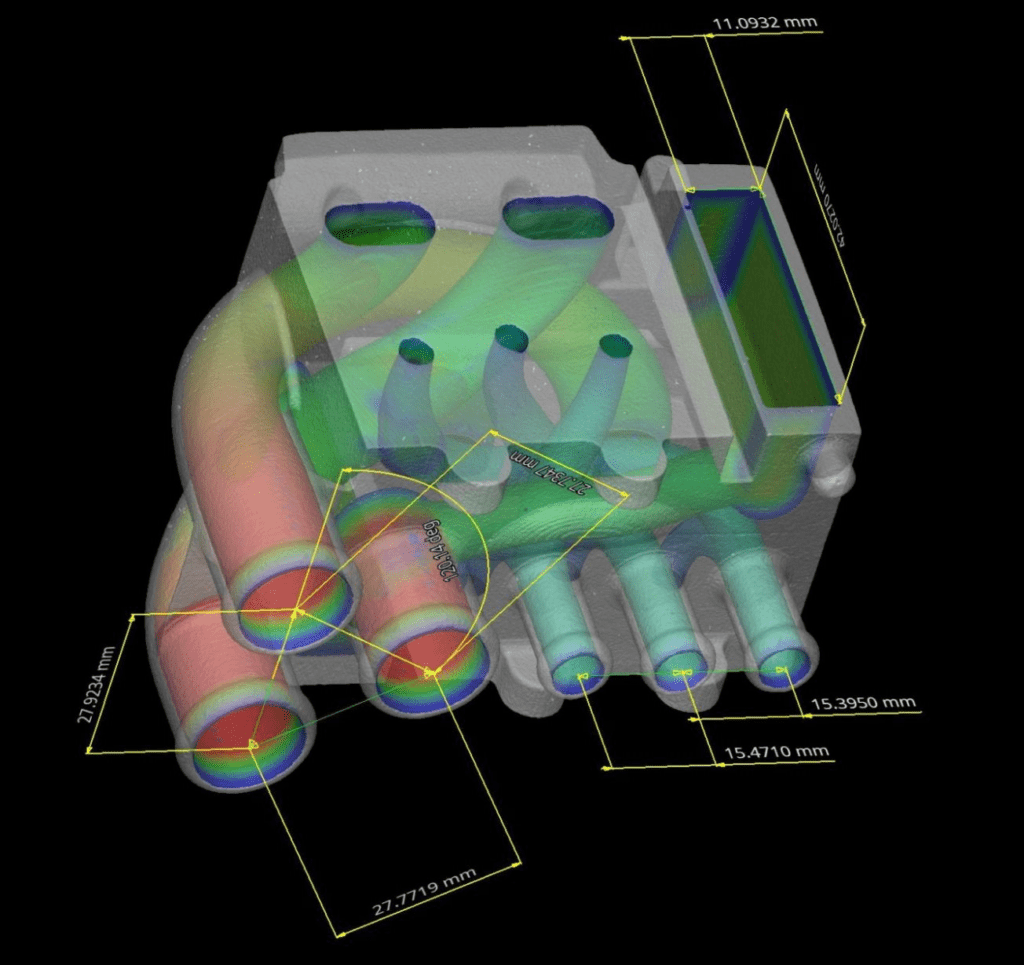

While almost everyone knows CT scans are utilized in the medical field, few are aware that they also have an industrial application as well! Computational Tomographs utilize X-ray (Röntgen) radiation in order to map external and primarily internal geometry otherwise not seen by the naked eye. This is especially helpful for complex components which have internal geometries, for example for a flow path or hollow sectors, or alternatively to detect pores, defects and other inclusions in castings. Combined with sophisticated CAD software wall thicknesses may be measured in a non-destructive manner meaning no damage done to any of the parts.

How does Computed Tomography work?

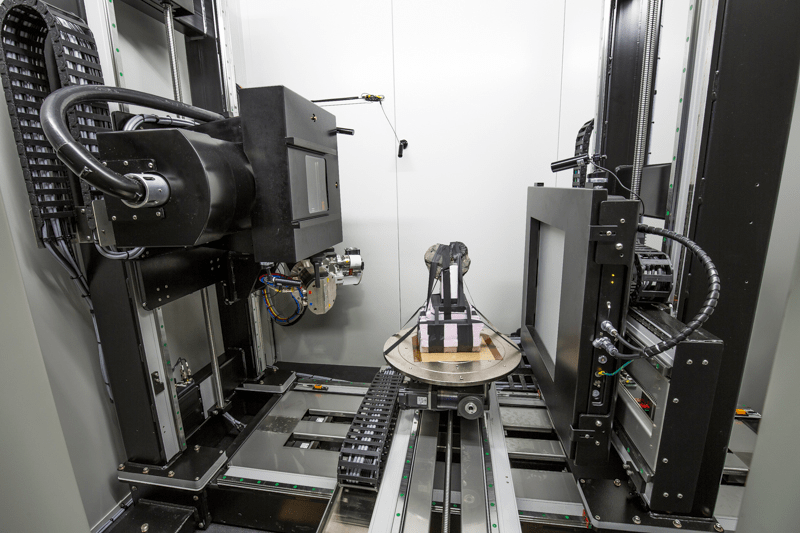

Industrial computed tomography (CT) scans work by irradiating an object in three dimensions with high-energy X-rays, to map internal and external geometries of the scanned object. It is often used for flaw detection, failure analysis, metrology and engineering applications. CT scanning can detect internal features and flaws displaying this information in 3D without destroying the part. The object to be measured is placed into an industrial CT scanner, proper safety precautions are taken to ensure safe operation, and then the part is examined.

Flaw Detection, Geometrical Inspection and Analysis

One of the most recognized forms of analysis using CT is for assembly, or visual analysis. CT scanning provides views inside components in their functioning position, without disassembly. Traditionally, determining defects, voids and cracks within an object would require destructive testing. Dependent on part size, measuring volumes, resolution and beam intensity, resolutions can be achieved from anywhere between 200 to 5 µm. In general, this allows for the purpose of geometrical and dimensional data capture for (reverse) engineering purposes, as well as flas detection, inspection, analysis etc. In general the smaller the part, measuring volume and higher the beam intensity, the higher the resolution of the scan.

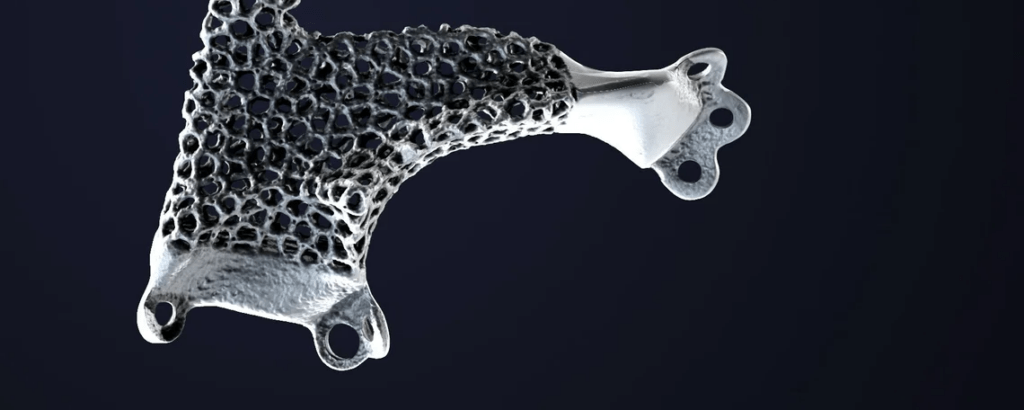

CT and Additive Manufacturing (3D Printing)

Modern problems require modern solutions or so they say! Additive manufacturing (AM) is a perfect example of a perfect match between modern manufacturing and modern metrology methods. Additive manufacturing allows for flexible manufacturing including complex internal cavities and structures, that can only be achieved by 3D printing metallic alloys. This makes CT scans perfect for any aerospace, marine, medical or other field requiring high-accuracy and intricate components.

Want to learn more? Contact us below: