Alloy Consulting

Selecting the right alloy can prove difficult, especially if your equipment is ageing and/or if for example the original material manufacturer is no longer in business. In addition, processes such as coatings and thermal treatments may be an option to increase operational life of components.

Our mission is to source such difficult-to-acquire alloys from a reputable network of vendors and mills, whom are often also OEM suppliers for the aerospace, nuclear or energy sectors. When it becomes difficult to locate such grades, selecting a modern alternative is sometimes a good value proposition for the client. Moreover, our key competences are in advising clients on alternative options to consider for materials in their applications, to recommend ways to increase component lifetime and decrease operational costs.

Alloy Search’s expertise allows us to advise our clients in selecting a top-quality grade for their assets’ application, taking into account for example properties like chemical composition, mechanical strength, ductility, weldability, corrosion resistance, properties at elevated temperatures or cryogenics.

Another key aspect to consider is material availabilty and overall fit with the client’s project timeline, whether it be an overhaul of a key asset, refurbishment of internal components or retrofit / upgrade of an existing installation, Alloy-Search has the capability to advise our clients by selecting a material grade that fits their overall needs and without compromising on quality.

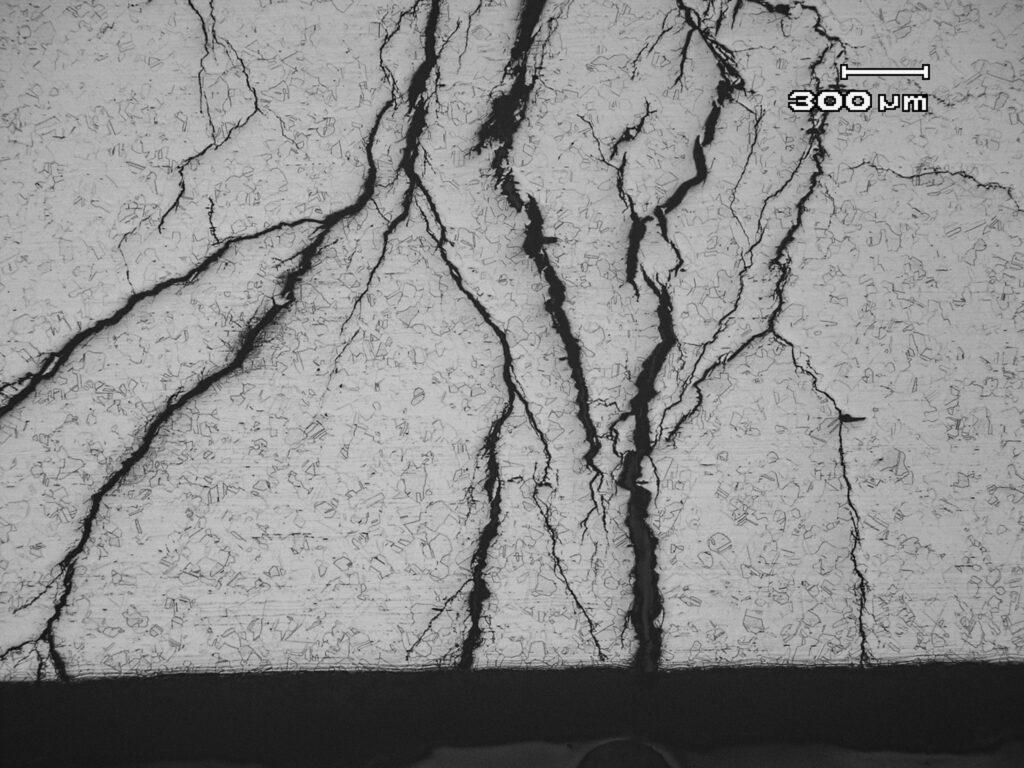

Stress Corrosion Cracking SCC

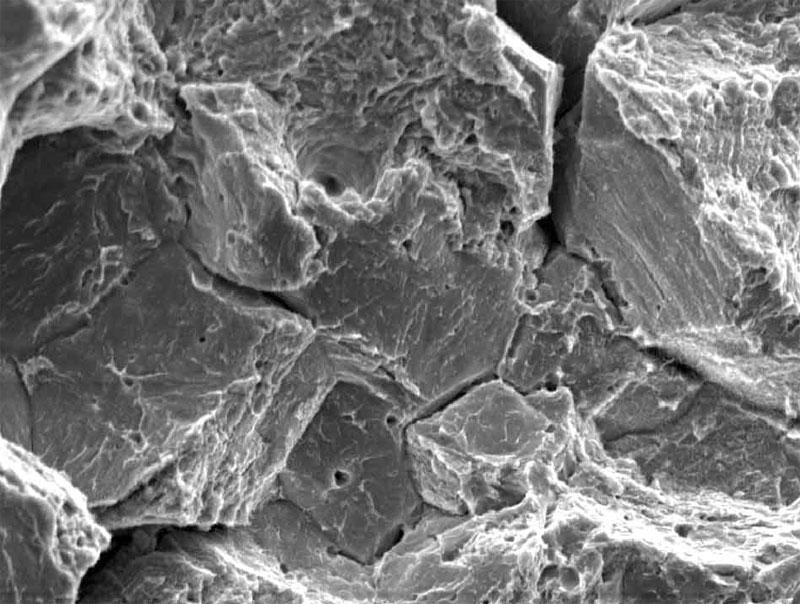

Hydrogen Embrittlement HE

Plasma- & Ion Nitriding

Thermal Spray Coatings